Cheaper materials could be key to low-cost solar cells

| 17 February 2009

BERKELEY — Unconventional solar cell materials that are as abundant but much less costly than silicon and other semiconductors in use today could substantially reduce the cost of solar photovoltaics, according to a new study from the Energy and Resources Group and the Department of Chemistry at the University of California, Berkeley, and the Lawrence Berkeley National Laboratory (LBNL).

These materials, some of which are highly abundant, could expand the potential for solar cells to become a globally significant source of low-carbon energy, the study authors said.

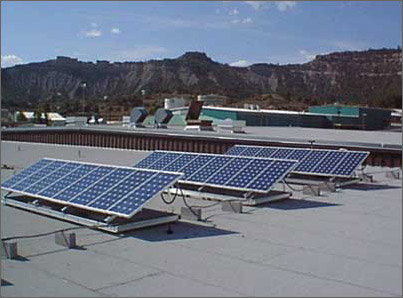

Solar power collectors, like these photovoltaic panels on a New Mexico high school roof, could be installed much more widely if they could be manufactured from less-costly materials. (U.S. Department of Energy photo)

Solar power collectors, like these photovoltaic panels on a New Mexico high school roof, could be installed much more widely if they could be manufactured from less-costly materials. (U.S. Department of Energy photo)The work provides a roadmap for research into novel solar cell types precisely when the U. S. Department of Energy and other funders plan to expand their efforts to link new basic research to deployment efforts as part of a national effort to greatly expand the use of clean energy, according to Daniel Kammen, UC Berkeley professor of energy and resources and director of the Renewable and Appropriate Energy Laboratory.

Kammen and colleagues Cyrus Wadia, a post-doctoral researcher at LBNL, and A. Paul Alivisatos, interim director of LBNL and UC Berkeley professor of chemistry, embarked on an intensive research project to explore the question of whether high-impact materials have been overlooked or underdeveloped during the last several decades of solar cell research.

“The reason we started looking at new materials is because people often assume solar will be the dominant energy source of the future,” said Wadia, a post-doctoral researcher who spearheaded the research. “Because the sun is the Earth’s most reliable and plentiful resource, solar definitely has that potential, but current solar technology may not get us there in a timeframe that is meaningful, if at all. It’s important to be optimistic, but when considering the practicalities of a solar-dominated energy system, we must turn our attention back to basic science research if we are to solve the problem.”

The most popular solar materials in use today are silicon and thin films made of CdTe (cadmium telluride) and CIGS (copper indium gallium selenide). While these materials have helped elevate solar to a major player in renewable energy markets, they are still limited by manufacturing challenges. Silicon is expensive to process and mass produce. Furthermore, it has become increasingly difficult to mine enough silicon to meet ever-growing consumer demand.

Thin films, while significantly less costly than silicon and easier to mass produce, would rapidly deplete our natural resources if these technologies were to scale to terawatt hours of annual manufacturing production. A terawatt hour is a billion kilowatt hours.

“We believe in a portfolio of technologies and therefore continue to support the commercial development of all photovoltaic technologies,” Kammen said. “Yet, what we’ve found is that some leading thin films may be difficult to scale as high as global electricity consumption.”

“It's not to say that these materials won't play a significant role,” Wadia added, “but rather, if our objective is to supply the majority of electricity in this way, we must quickly consider alternative materials that are Earth-abundant, non-toxic and cheap. These are the materials that can get us to our goals more rapidly.”

The team identified a large material extraction cost (cents/watt) gap between leading thin film materials and a number of unconventional solar cell candidates, including iron pyrite, copper sulfide and copper oxide. They showed that iron pyrite is several orders of magnitude better than any alternative on important metrics of both cost and abundance. In the report, the team referenced some recent advances in nanoscale science to argue that the modest efficiency losses of unconventional solar cell materials would be offset by the potential for scaling up while saving significantly on materials costs.

Finding an affordable electricity supply is essential for meeting basic human needs, Kammen said, yet 30 percent of the world’s population remains without reliable or sufficient electrical energy. Scientific forecasts predict that to meet the world’s energy demands by 2050, global carbon emissions would have to grow to levels of irreversible consequences.

"As the U.S. envisions a clean energy future consistent with the vision outlined by President Obama, it is exciting that the range of promising solar cell materials is expanding, ideally just as a national renewable energy strategy takes shape," said Kammen, who is co-director of the Berkeley Institute of the Environment and UC Berkeley's Class of 1935 Distinguished Chair of Energy.

The study by Wadia, Kammen and Alivisatos, available online at http://pubs.acs.org, will appear in the March print issue of Environmental Science & Technology. Wadia will discuss the report on April 14 at the upcoming spring meeting of the Materials Research Society, to be held at the Moscone Center in San Francisco.

The work was supported by the U.S. Environmental Protection Agency, the Energy Foundation, the Karsten Family Foundation Endowment of the Renewable and Appropriate Energy Laboratory and the Class of 1935.